The textile industry has long required precise handling of delicate materials. With advancements in material handling equipment, forklifts equipped with specialized attachments have become essential tools. These forklifts are tailored to meet the industry's unique demands, enhancing efficiency, safety, and material protection.

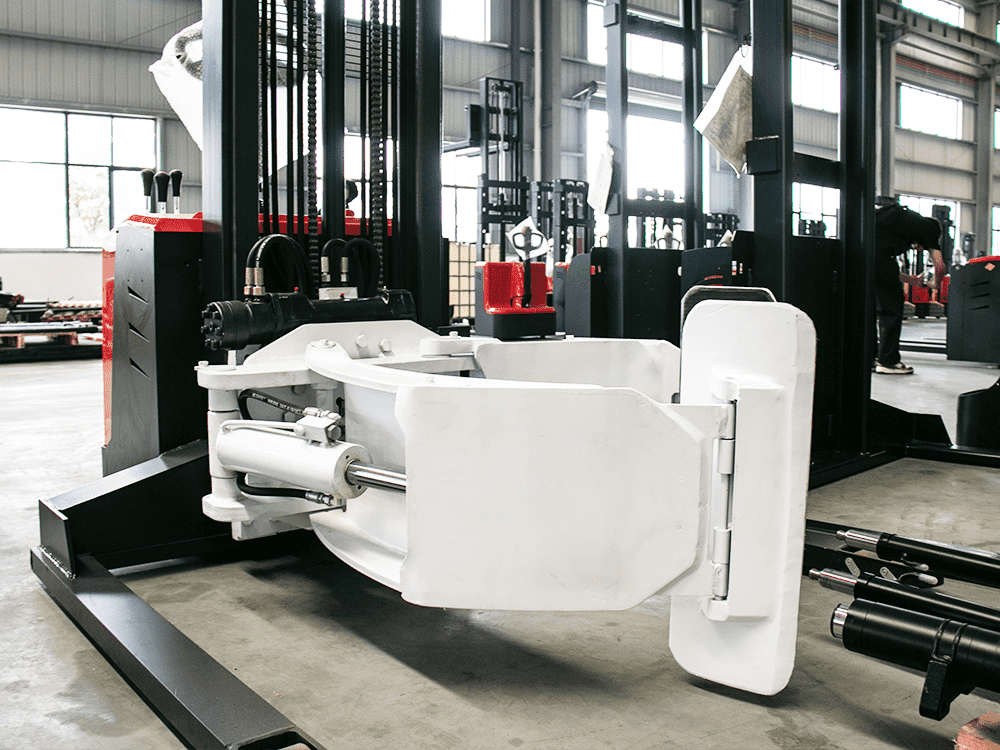

In textile mills and warehouses, forklifts with roll clamps handle large fabric rolls with care, preventing damage and ensuring smooth transport. The ability to securely grip and move these rolls without causing tears or distortions is crucial, saving costs and maintaining quality.

Standard forklifts can be customized with attachments like fork extensions and platforms to transport palletized goods. This versatility is vital in an industry where materials range from raw fibers to finished Products. Efficiently moving these goods keeps production on track and meets delivery deadlines.

Loading and unloading operations benefit significantly from forklifts with specialized attachments. These tools streamline processes, reduce labor, and boost productivity by adapting to various packaging types common in textiles. Optimizing storage space is another critical advantage, achieved with side shifters and multi-directional attachments, allowing precise placement and easy retrieval of goods.

Modern forklifts are increasingly integrated with automation technology. Automated guided vehicles (AGVs) with textile-specific attachments handle materials unmanned, cutting labor costs and enhancing efficiency. Safety innovations, such as load sensors and stability control, protect operators and materials, ensuring reliable performance.

Electric forklifts are also making a mark in the textile industry. These eco-friendly machines reduce emissions and noise, perfect for indoor use. They support the industry's push towards sustainability while promoting a cleaner, quieter working environment.

Customization is key in the textile industry. Forklifts with adjustable roll clamps and specialized cradles optimize material handling processes, enhancing efficiency and ensuring careful handling of textiles.

As the textile industry evolves, the role of forklifts with specialized attachments becomes increasingly critical. Future trends include AI and IoT integration for real-time monitoring and predictive maintenance, further boosting efficiency and reducing downtime. The development of lightweight yet robust materials for attachments ensures forklifts handle larger and more delicate loads safely.

Forklifts with specialized attachments are indispensable in the textile industry. Their precision and ongoing technological advancements make them vital for the industry's logistics and material handling operations. As the industry moves towards greater automation and sustainability, these versatile machines will continue to enhance efficiency and productivity.