Introduction

No matter what, be it logistics or manufacturing, efficient material handling is a key operation in the success of operations. Counterbalance forklift among the different types of material handling equipment used to transport and stack goods is one of the most efficient, versatile, and resourceful machines available on a production floor. They are built to bear various weights and volumes which makes them a must-have in a warehouse as well as on the factory floor. Here, we will explain how different counterbalance forklift truck benefits can help enhance your material handling operations.

Counterbalance Forklift Truck Guide

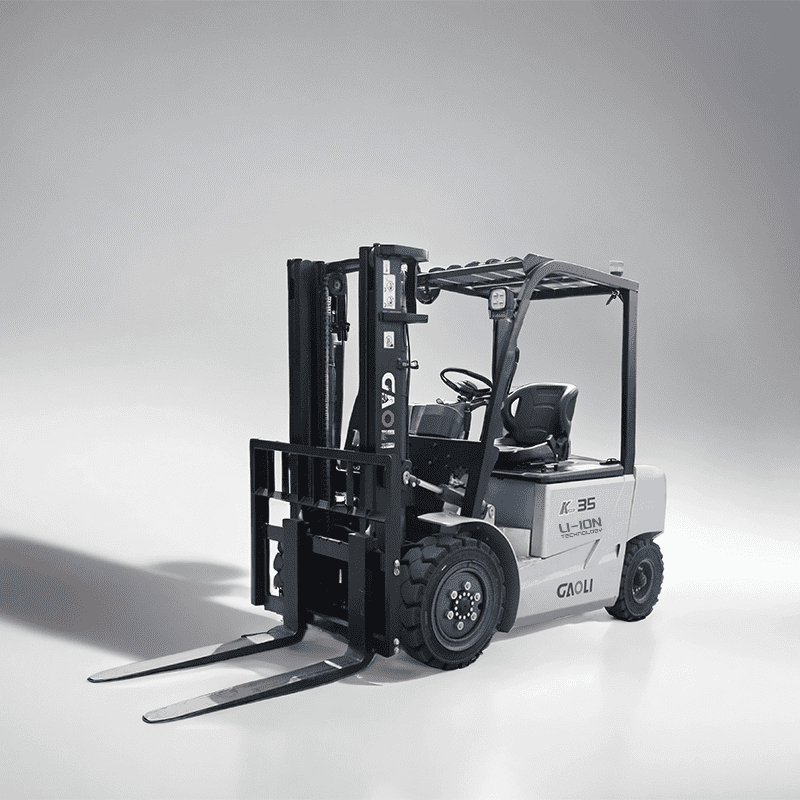

As their name suggests, counterbalance forklift trucks are designed to counterweight the loads that they carry — unlike many other types of fork lift truck, where a more complicated mechanism allows them to perform this function. Some of those variants are internal combustion engine powered, some are electrified and others use your lithium-ion batteries for unlimited efficiency & zero-emission. The main components of this kind are in Counterbalance Forklifts below: Mast (Used for loading raising) Drive system (For driving a truck, which consists of all types of tires.)

Benefits of Counterbalance Forklift Trucks

One of the key reasons for the popularity of counterbalance forklift trucks in material handling is their numerous advantages.

Better Payload Traction: Thanks to being categorized as light to heavy load vehicles, they can be utilized for a wide range of tasks They have high lifting heights so they can reach up into storage racks.

Higher Nimbility And Accuracy: Compact counterbalance forklifts travel through narrow spaces and stacked up warehouses with ease. With the expansion of newer control models, you will need accurate movement to ensure that loading and unloading occur successfully.

Applicable for Pretty Much Any Application: These trucks can function both indoors and out, on a wide range of different surface/environment. Each industry need can customize the forklift.

Enhanced safety features: a counterbalance forklift truck is maximally made safe today than ever before in history by employing such feature as through the assistance of labour roll cages and overhead guards with other safety technologies.

Gains from Productivity and Efficiency

Forklift Trucks offer a significant boost in productivity and efficiency when incorporated into material handling operations.

Quick Transportation of Goods: they are also capable of transporting materials from one place to another quickly with less time loss thus accelerating the sequence of events.

Improved Space Efficiency and Utilization: Counterbalance forklifts are so stackable simple that they help to store more materials, so this helps especially in high-density storage areas!

Increased Productivity and Labor savings: The productivity benefits attributable to counterbalance forklift usage can result in increased throughput as well as substantial labor and material handling cost reductions.

Environmental Considerations

Step-Up In Priority Upward: Environmental Impact Of Material Handling Equipment

This means that, especially in the counterbalance forklift truck sector, many (if not most) new machines are powered by electric or lithiumion sources, which deliver clean running benefits whilst improving overall machine energy efficiency.

Carbon footprint & emission reduction: Eco-friendly models help businesses factor into their carbon footprints and emit less.

Environmental Regulations: Obviously, this is a no-brainer and most modern lifts comply with or surpass environmental regulations.

Maintenance and Reliability

Preparations To Make If Performing Routine Maintenance Customer Care November 8, 2022 by Significance Of Regular Maintenance & Check-Ups Routine maintenance and service allows counterbalance forklift trucks (CB Task) to skyrocket properly, a lot more efficiently & without the chance of therapeutic about.

Dependability for Mission Critical Applications: Another aspect is when downtime will translate to a world of hurt in dollars and cents, the manufacturer needs a forklift that they can rely on.

Manufacturers And Vendors Support: There are few manufacturers that do support maintenance services of this truck to make it operational.

Conclusion

From increased lifting capability and maneuverability to more safety features and environmental reciprocity, counterbalance forklift trucks provide a range of advantages. When you add those advantages, and factor in total cost of ownership, that will set any business up to welcome this most powerful of machines in its day-to-day lives.